HecKits LC Meter Kit Build |

L/C Meter Kit Build

By Chris Prioli, AD2CS

It’s that time again. Back at the build bench, with another HecKits (www.heckits.com) project. This time, it’s an L/C Meter. This is a digital meter for measuring the inductance of a coil or the capacitance of a capacitor. According to the unit documentation, the range of the capacitance meter is 0.0 picoFarads to about .1 µFarads, and the inductance range is 0.0 µHenrys to about 10 mHenrys. The meter also displays values in nX where X is either a capacitance or inductance value. This meter works by measuring the frequency of an oscillator which is operating with the unknown value as one of its elements. That frequency is compared to a calibration frequency and the mathematics is done to determine the value of the unknown device under test.

Introduction

The documentation explains that this meter is a variation of another meter explained at Phil Rice VKEBHR’s website : https://sites.google.com/site/vk3bhr/home. I spent some time on that site, reading about Phil’s version of the meter. His meter design was an outgrowth of his lack of desire to do the math he used to do when measuring small coils, based on their frequency effect in a one-transistor oscillator circuit.

The HecKits version uses software from an Indonesian author, and as a result, the screen prompts are not in English. In reality, the HEX code is a derivative of VK3BHR’s software, rewritten by an Indonesian ham, YC3TKM. At first, the non-English prompts bothered me, but I quickly got used to them. I will, however, eventually find the time to rework the code to provide English prompts for my build of the meter. I will say that the actual readings use the familiar C and H values, with appropriate prefixes.

Pre-use zeroing of the meter is done in two different ways, depending on the mode to which the meter is set. When set to capacitance, the “zero” set is made with the test terminals open, while in inductance mode, the test terminals or leads are shorted for zeroing.

This meter uses the same form factor enclosure as the previous HecKits build about which I wrote, the FET DIP Meter. Again, we have an LCD panel at the upper end of the meter face. The kit ships with a non-backlit LCD panel. I chose to change that, and so I supplied and installed a backlit LCD panel during my build - more on that later.

Another familiar point is that there are no legends of any kind on the PCB - no component outlines, values, or component ID’s. This is one area where I believe that HecKits could really do a better job. Additionally, the front panel labeling of the unit is another shortcoming, in that there is none supplied. I resolved this issue by printing my own label to affix to the front face.

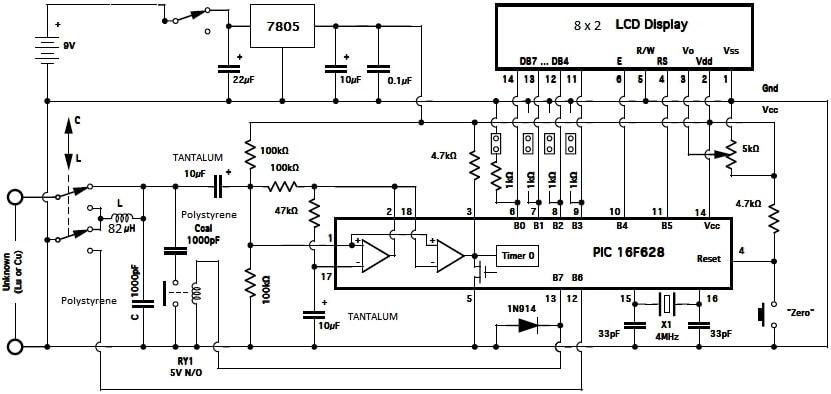

Refer to Figure 1 for a schematic of the meter. The heart of the unit is a PIC16F628 microcontroller in a DIP-18 package. The µC ships pre-programmed and ready to install in the provided DIP socket. Power is supplied by a standard 9V battery (not provided), and is regulated to the requisite 5VDC by an LM7805 three-pin voltage regulator IC. A DPDT latching pushbutton switch is used to select the operating mode, another one as the power switch, and a momentary version is used to zero the meter. There are a total of nine capacitors used, in a mixture of tantalum, aluminum electrolytic, polystyrene, and ceramic types. An 82µH inductor is also used. The resistor complement is made up of ten quarter-watt resistors in four values, and a single pole, single throw single-inline relay is employed, with a 1N4148 diode across the relay coil for spike suppression. The LCD panel is a two-line, eight characters per line device wired for 8-bit operation, and a 5KΩ trimmer potentiometer is provided for LCD contrast adjustment. The µC clock is set by a 4 MHz crystal. That’s the whole shooting match for the main unit, apart from some four-pin headers, a couple of ninety-degree headers (one six pins and one four), a battery snap, wire pigtails, and some hardware including a pin jumper and three switch caps. Figure 2 displays the parts spread for the main unit. An accessory kit, shown in Figure 3, includes the components to assemble the device-under-test (DUT) adapters and the test leads. The test jacks are pre-installed to the main PCB and accessory PCB’s as shipped.

As with the previous HecKits build, a rudimentary wooden stick and sheet metal nut driver to fit the 2-56 hex nuts used in the unit is included in the kit. The main PCB and the LCD panel are shipped secured in place in the enclosure, as seen in Figure 4. In order to assemble the unit, the boards must be removed from the enclosure. Be sure to set the hex nuts aside in a secure place so that you can find them when it becomes time to re-install the boards. The hex nuts are tiny and are easily lost. The bare main PCB is shown in Figures 5 and 6. Note the pre-installed test jacks on the component side of the PCB

Assembly

Assembly starts with installing the lowest-profile components to the main PCB. Those components are the resistors, the inductor, and the diode. Identify the specific locations of each of the resistors by referring to the circuit board layout diagram in the build instructions. Once you are certain that you have each of the resistors in its correct location, solder it in place and clip off the excess lead length. The 1N4148 diode is installed with its cathode end towards the center of the board, alongside the SIP relay position.

Install the 18-pin DIP socket (with its notched end toward the end of the PCB with the test jacks installed), the four-pin two-by-two pin headers (Figure 7), the six-pin and four-pin right-angle pin headers, and the 5kΩ trim pot. Follow that with the various capacitors, observing component values and also noting the polarity of the two 10µF tantalum, the 22µF electrolytic, and the 10µF electrolytic capacitors.

When installing the two 1000pF (0.001µF) axial polystyrene film capacitors, install them on end down against the PCB with the opposite lead in the correct hole as indicated on the component layout diagram. While these two capacitors are not polarized per se, the installation direction does often make a difference. When installing metal plastic film capacitors, it is recommended that the outside foil end of the capacitor be installed to the lower impedance side of the circuit, usually to ground. In the case of the capacitors included with my kit, which had no manufacturer’s marks other than a “1000” for the picoFarad value, the outside foil end could be visually identified by looking through the clear plastic body of the capacitor. The foil roll inside the capacitor is closer to one end than it is to the other. The end away from the rolled coil is the outside foil end, as can be seen by looking carefully at the visible lead inside. This end of the capacitor should go DOWN on the capacitor nearer the edge of the PCB, and it should go UP on the capacitor nearer the center of the PCB. A quick look at the PCB diagram shows that the capacitor near the center of the PCB is grounded through the relay contacts, while the other one is directly tied to ground.

It is unknown whether or not this level of care is actually necessary in this design. However, this installation direction is standard for foil-type capacitors, and as such is the best practice and therefore should be followed. Many designers depend on the inherent shielding provided by this installation direction to minimize noise pickup in the capacitors, and the oscillator will certainly radiate some noise.

Install the SIP relay to the PCB. This device is pin-symmetric, so installation direction does not matter. Also install the 4 MHz crystal and the LM7805 TO-220 voltage regulator IC. The LM7805 needs to have its leads bent at ninety degrees downward in relation to the marked surface of the IC body. The IC in my kit was pre-bent, but that may or may not be standard practice. If yours is unbent, be sure to bend it before installation.

When performing the next step, installation of the three pushbutton switches, be sure to install the two latching switches in the center and left-hand locations, when viewed from the component side of the board. Finally, solder the battery clip leads in place, observing red/black positive-negative polarity as indicated on the circuit board component layout diagram.

Once the main PCB is complete, as shown in Figure 8, it is time to wire the LCD board. The board will get a total of ten wires soldered to it, in two groups. There are two wire pigtails with plugs in the kit remnants, one with six wires, and one with four wires. The six-wire one has, in order from one end of the plug to the other, a brown, a red, an orange, a yellow, a green, and a blue wire. These wires will be inserted and soldered, respectively, into holes 1 through 6 on the LCD board. Similarly, the four-wire piece has, again in order from one end to the other, a brown, a red, an orange, and a yellow wire. These wires will go into holes 11 through 14, in sequence starting with the brown wire. The graphic at Figure 9 will show which wire color goes into which PCB hole. Solder these wires in place as well. These wires all go in from the side of the PCB with the hole numbers, and are soldered on the side with the LCD screen. It should be noted that the documentation parts list calls for right-angle plugs on these wire pigtails, but the ones in my kit were zero-degree types. The completed LCD board is shown in Figure 10.

After soldering the wires to the LCD board, the next step is to check the operating voltages on the boards. Plug both of the wire plugs from the LCD board onto the right-angle headers on the main board, with the brown wires to the left in each case when looking at the component side of the board. Snap a fresh nine-volt battery onto the battery snap and turn the unit on by pressing the left-hand latching pushbutton switch. Next, using a voltmeter, measure the voltage at pin 14 of the IC socket and at pin 2 of the LCD panel. Both locations should measure a nominal five volts. If the voltage is OK, you can move on with the assembly. If the voltage is not correct, check the installation and soldering of the LM7805 voltage regulator as well as the battery snaps. Start by verifying nine volts at pin 1 of the LM7805. If the nine volts are present but the five volts are not, check the installation and soldering of the 10µF electrolytic and the 0.1µF ceramic capacitors at pin 3 of the LM7805 voltage regulator. If no soldering errors such as solder bridges are found, the voltage regulator IC may be faulty.

If the five-volt supply is correct, shut the unit down and carefully install the PIC16F628 µC into the IC socket, observing the correct installation direction. Properly installed, the dotted or notched pin 1 end of the µC IC will be towards the test jack end of the main PCB. Be sure to get all eighteen pins into their slots in the IC socket without missing the socket to the outside and without allowing any pins to fold under the IC. It is sometimes helpful to gently press the IC at an angle on a tabletop to very gently and very slightly bend each row of pins towards the middle of the IC body.

Disconnect the battery from its snap. Then gently press a switch cap onto each of the pushbutton switches, aligning the shape of the switch shafts to the openings in the underside of the switch caps. Press them on until they snap into place.

Install the LCD panel into its opening in the upper half of the enclosure, aligning the four holes onto the studs and securing it there by gently tightening a 2-56 hex nut onto each stud. DO NOT over tighten the hex nuts. Remove the battery compartment cover from the lower half of the enclosure and pass the battery snap through the resulting opening. Align the main circuit board onto its four studs and secure it there with the 2-56 hex nuts provided. Again, DO NOT over tighten the hex nuts (Figure 11).

Snap the battery back onto its snap and then turn the meter on by depressing the left-hand pushbutton switch on the front panel. Using a small screwdriver, carefully adjust the 5kΩ trim pot until the display is visible without “shadow boxes” behind the characters. Turn the meter off.

Calibration

There are several facets to the calibration of the meter. The first is to check the free-running frequency of the oscillator and the calibration frequency of the oscillator. The calibration frequency should be within 71% ±10% of the free-running frequency. Calibration involves the use of the jumper pin cap and the four two-pin jumper headers on the main PCB. Figure 12 shows the locations of the four jumper headers.

We can check the free-running oscillator frequency (F1) first by taking the jumper cap and placing it on the two pins of J2, the second pair of jumper pins from the top of the PCB. Turn the unit on and the display will show the frequency in Hertz. With the 82µH inductor in circuit, the oscillator will run somewhere in the range of 58 kHz to 60 kHz. Mine runs right at 58.922 kHz - 0058922 on the meter display (Figure 13). To see the calibration frequency (F2) displayed, move the jumper cap to J1 - the first pair of pins from the top of the PCB. The display will now show the calibration frequency. Mine ran at 41.771 kHz (00041771 on the meter - Figure 14). This equates to 70.89% of the free-running frequency, and well within the ±10% frequency tolerance. It should be noted that if there is an indication of “0000000” on the display while checking oscillator frequencies, the oscillator is not running and some investigative work is called for. Also, if the difference between the free-running frequency and the calibration frequency is less than 2%, the relay is suspect. The two frequencies were measured using my bench-top frequency counter and found to be within 5 hertz of the displayed values.

The jumper cap is also used to calibrate the capacitance meter, if calibration is needed. To make that determination, start out by setting the meter in capacitance mode (center switch out) and then zeroing the capacitance function by momentarily pressing the right-hand switch. The meter will go through its calibration routine and will display “C = 0.0pF”. At this point, connect your standard capacitor - a device of a definite known value or a high-precision device - to the meter and read the display. If the meter reads within the tolerance of the capacitor, no calibration is required. For example, if your standard is a 0.001µF (1000pF) capacitor with a ±10% tolerance, the meter should read between 900 and 1100 picoFarads.

If the reading is outside the tolerance limits of your standard capacitor, calibration is accomplished by applying the jumper cap to either J3 or to J4. J3 is the third set of jumper pins from the top of the PCB, and J4 is the fourth set. Connecting the jumper cap to J3 will yield a decrease in indicated capacitance, while applying the jumper cap to J4 will produce on increase in displayed capacitance. The capacitance reading will continue to go up or down as long as the jumper is connected. When the reading gets to the value that you require for your capacitance standard, remove the jumper cap. The µC will remember the calibration value and use it in future measurements. Store the jumper cap by placing it on only one of the pins at J1 so that it is available if needed in the future.

Inductance calibration is automatically accomplished when the capacitance calibration is set.

Accessory Kit

The accessory kit assembly involves soldering alligator clips to the two test lead which are already terminated with banana pins, and the assembly of two miniature adapter circuit boards. One of the adapters - the LC adapter - gets only a four-pin SIP socket. The banana pins are already soldered in place as shipped. The second adapter is a varactor diode adapter, used for measuring the capacitance of a varactor diode. It has a pair of 100kΩ resistors and a 1µF monolithic ceramic capacitor in addition to the four-pin SIP socket. The assembled accessory kit is shown in Figure 15.

Final assembly requires that the LCD panel wires be plugged onto the main PCB right-angle headers, with the brown wires to the left on both plugs. Arrange the wires so that they will curl under the upper half of the enclosure cover, and install the end plate into the grooves in the enclosure end. Bring the two halves of the enclosure together, aligning the end plate into the slots in the second half and the three switches into their holes, and hold the two halves together while installing the four black securement screws provided for this purpose. Arrange the battery into the battery section and install the battery section cover to the lower half of the enclosure. If desired, print and affix a front panel label to the meter, and the job is complete (Figures 16 and 17).

Backlit LCD Panel

As I mentioned earlier in this article, I opted to replace the supplied non-backlit LCD panel with a backlit one. The original LCD panel is a Crystalfontz CFAH0802A-NYG-JT# 8X2 sunlight readable LCD unit. The backlit unit that I used is a Crystalfontz CFAH0802-YYH-JT# unit, which includes a 5VDC yellow-green LED backlight.

In order to make the backlight work, some modifications are necessary to the backlit LCD panel. These modifications consisted of closing one jumper location with a solder bridge, and soldering in a current limiting resistor at another location.

Refer to Figure 18 and note the locations identified as RA and J2 at the end of the LCD panel PCB opposite the end with the wire holes. One end of the RA location is connected through the PCB traces to Pin 2 of the PCB, which is the incoming 5VDC point. Similarly, one end of J2 is connected through the PCB traces to Pin 1 of the PCB, which is the 0VDC or ground pin. The opposite end of RA is tied to the A location, which is the anode of the backlight LED, and the second pin of J2 is tied to the K location, which is the backlight LED cathode.

Creating a solder bridge across J2 effectively grounds the cathode of the backlight LED. The requisite current-limiting resistor gets installed across the RA location, thus completing the power circuit for the backlight LED and providing for proper current limitation.

So now, the question becomes “What value resistor should be used at RA to provide for the proper current to the LED?” That answer comes from the Crystalfontz datasheet for the CFAH0802-YYH-JT# unit. According to the datasheet, the backlight LED current is typically 70mA, and the forward voltage is listed as 4.2VDC. OK - a 5.0VDC supply less 4.2V leaves 0.8 volts. Using Ohm’s Law and solving for resistance, R = E / I so R is equal to 0.8V / 0.07A - remember that we have to convert the 70mA to amperes. The resulting resistance would be 11.43Ω. By the way… the standard formula for finding an LED limiting resistor from voltage and current is to use the formula R = (VS – VF) / IF which is really just another way of saying the same thing… R = (5.0-4.2) / 0.07 = 0.8 / 0.07 which is equal to 11.429Ω. Ohm’s Law through the back door!

I installed an 18Ω 250mW resistor and called it a day. I also did not even bother to source a surface mount resistor for this, as I had the axial leaded 18Ω part in stock. It was an OK fit soldered to the PCB at the RA location. I could have gone with a 15Ω (or even a 10Ω) resistor just as easily either one would have worked OK. I chose the 18Ω because it would reduce their current towards to lower end of the current range (63mA to 84mA), would dim the LED very slightly and would possibly slightly extend the LED life. The 250mW was overkill, as the resistor would consume a mere 56mW, but it was what I had on hand. Figure 19 shows the modified LCD panel as installed into the meter enclosure.

Conclusion

This meter will find a home on my test bench. Of that, there is no doubt. However, I won’t really be happy with it until I have re-worked the software to give me English prompts. To that end, I already stock a few pieces of the PIC16F628A-I/P microcontroller, so I am ahead of the game, especially as Mouse and Digikey have no stock on these µC’s as of the date of this writing. I do not plan to overwrite the original; instead, I will work with another IC for my experimentation. I will find the time to do that in the not-too-distant future. Some time with MPLAB is called for.

Apart from the non-English prompts, my other complaints about this kit are the lack of a front panel label - an easy and inexpensive improvement that the kit maker should consider, especially as it would get his brand out there to be seen and remembered - and the complete lack of PCB legend screen prints. I mentioned this with the last HecKits build, and it is still a sore spot. I know that with my PCB manufacturer, there is no additional charge for the screen printing, so this is truly an egregious oversight in my opinion. It is one of the things that takes a first-class kit and relegates it to the lower levels, and certainly makes the build more onerous. My last gripe is that the parts actually shipped do not accurately match the parts list provided. Either provide the listed parts, or edit the parts list! I also think that a backlit LCD panel should be the standard equipment alternative rather than a builder-supplied upgrade.

So much for the cons… now for the pros. The meter is quick and responsive, and is more than adequately accurate. I like its compact size, and I appreciate the attention to detail expended in the mounting arrangements for the circuit boards. The fact that the maker provides the rudimentary nut driver says quite a bit. Someone thought about the limited clearance around some of the fastening hex nuts and provided a tool solution to make assembly simpler. The mounting studs or screws are locked in place, making installation of the boards a breeze. The battery compartment includes a rubber pad to keep the battery from rattling around, and the battery snap is of sturdy good quality. The kit maker’s decision to pre-solder the test jacks and banana pins was a good choice, as they are critical points that could be difficult for a less-experienced kit builder. The fit and finish of the meter is good.

All things considered, this one is probably a B+, but it would not take much to make it an A+. As HecKits grows, I would expect that some of these issues will be addressed. They need to be, because they really keep this from being a first-rate kit.

By Chris Prioli, AD2CS

It’s that time again. Back at the build bench, with another HecKits (www.heckits.com) project. This time, it’s an L/C Meter. This is a digital meter for measuring the inductance of a coil or the capacitance of a capacitor. According to the unit documentation, the range of the capacitance meter is 0.0 picoFarads to about .1 µFarads, and the inductance range is 0.0 µHenrys to about 10 mHenrys. The meter also displays values in nX where X is either a capacitance or inductance value. This meter works by measuring the frequency of an oscillator which is operating with the unknown value as one of its elements. That frequency is compared to a calibration frequency and the mathematics is done to determine the value of the unknown device under test.

Introduction

The documentation explains that this meter is a variation of another meter explained at Phil Rice VKEBHR’s website : https://sites.google.com/site/vk3bhr/home. I spent some time on that site, reading about Phil’s version of the meter. His meter design was an outgrowth of his lack of desire to do the math he used to do when measuring small coils, based on their frequency effect in a one-transistor oscillator circuit.

The HecKits version uses software from an Indonesian author, and as a result, the screen prompts are not in English. In reality, the HEX code is a derivative of VK3BHR’s software, rewritten by an Indonesian ham, YC3TKM. At first, the non-English prompts bothered me, but I quickly got used to them. I will, however, eventually find the time to rework the code to provide English prompts for my build of the meter. I will say that the actual readings use the familiar C and H values, with appropriate prefixes.

Pre-use zeroing of the meter is done in two different ways, depending on the mode to which the meter is set. When set to capacitance, the “zero” set is made with the test terminals open, while in inductance mode, the test terminals or leads are shorted for zeroing.

This meter uses the same form factor enclosure as the previous HecKits build about which I wrote, the FET DIP Meter. Again, we have an LCD panel at the upper end of the meter face. The kit ships with a non-backlit LCD panel. I chose to change that, and so I supplied and installed a backlit LCD panel during my build - more on that later.

Another familiar point is that there are no legends of any kind on the PCB - no component outlines, values, or component ID’s. This is one area where I believe that HecKits could really do a better job. Additionally, the front panel labeling of the unit is another shortcoming, in that there is none supplied. I resolved this issue by printing my own label to affix to the front face.

Refer to Figure 1 for a schematic of the meter. The heart of the unit is a PIC16F628 microcontroller in a DIP-18 package. The µC ships pre-programmed and ready to install in the provided DIP socket. Power is supplied by a standard 9V battery (not provided), and is regulated to the requisite 5VDC by an LM7805 three-pin voltage regulator IC. A DPDT latching pushbutton switch is used to select the operating mode, another one as the power switch, and a momentary version is used to zero the meter. There are a total of nine capacitors used, in a mixture of tantalum, aluminum electrolytic, polystyrene, and ceramic types. An 82µH inductor is also used. The resistor complement is made up of ten quarter-watt resistors in four values, and a single pole, single throw single-inline relay is employed, with a 1N4148 diode across the relay coil for spike suppression. The LCD panel is a two-line, eight characters per line device wired for 8-bit operation, and a 5KΩ trimmer potentiometer is provided for LCD contrast adjustment. The µC clock is set by a 4 MHz crystal. That’s the whole shooting match for the main unit, apart from some four-pin headers, a couple of ninety-degree headers (one six pins and one four), a battery snap, wire pigtails, and some hardware including a pin jumper and three switch caps. Figure 2 displays the parts spread for the main unit. An accessory kit, shown in Figure 3, includes the components to assemble the device-under-test (DUT) adapters and the test leads. The test jacks are pre-installed to the main PCB and accessory PCB’s as shipped.

As with the previous HecKits build, a rudimentary wooden stick and sheet metal nut driver to fit the 2-56 hex nuts used in the unit is included in the kit. The main PCB and the LCD panel are shipped secured in place in the enclosure, as seen in Figure 4. In order to assemble the unit, the boards must be removed from the enclosure. Be sure to set the hex nuts aside in a secure place so that you can find them when it becomes time to re-install the boards. The hex nuts are tiny and are easily lost. The bare main PCB is shown in Figures 5 and 6. Note the pre-installed test jacks on the component side of the PCB

Assembly

Assembly starts with installing the lowest-profile components to the main PCB. Those components are the resistors, the inductor, and the diode. Identify the specific locations of each of the resistors by referring to the circuit board layout diagram in the build instructions. Once you are certain that you have each of the resistors in its correct location, solder it in place and clip off the excess lead length. The 1N4148 diode is installed with its cathode end towards the center of the board, alongside the SIP relay position.

Install the 18-pin DIP socket (with its notched end toward the end of the PCB with the test jacks installed), the four-pin two-by-two pin headers (Figure 7), the six-pin and four-pin right-angle pin headers, and the 5kΩ trim pot. Follow that with the various capacitors, observing component values and also noting the polarity of the two 10µF tantalum, the 22µF electrolytic, and the 10µF electrolytic capacitors.

When installing the two 1000pF (0.001µF) axial polystyrene film capacitors, install them on end down against the PCB with the opposite lead in the correct hole as indicated on the component layout diagram. While these two capacitors are not polarized per se, the installation direction does often make a difference. When installing metal plastic film capacitors, it is recommended that the outside foil end of the capacitor be installed to the lower impedance side of the circuit, usually to ground. In the case of the capacitors included with my kit, which had no manufacturer’s marks other than a “1000” for the picoFarad value, the outside foil end could be visually identified by looking through the clear plastic body of the capacitor. The foil roll inside the capacitor is closer to one end than it is to the other. The end away from the rolled coil is the outside foil end, as can be seen by looking carefully at the visible lead inside. This end of the capacitor should go DOWN on the capacitor nearer the edge of the PCB, and it should go UP on the capacitor nearer the center of the PCB. A quick look at the PCB diagram shows that the capacitor near the center of the PCB is grounded through the relay contacts, while the other one is directly tied to ground.

It is unknown whether or not this level of care is actually necessary in this design. However, this installation direction is standard for foil-type capacitors, and as such is the best practice and therefore should be followed. Many designers depend on the inherent shielding provided by this installation direction to minimize noise pickup in the capacitors, and the oscillator will certainly radiate some noise.

Install the SIP relay to the PCB. This device is pin-symmetric, so installation direction does not matter. Also install the 4 MHz crystal and the LM7805 TO-220 voltage regulator IC. The LM7805 needs to have its leads bent at ninety degrees downward in relation to the marked surface of the IC body. The IC in my kit was pre-bent, but that may or may not be standard practice. If yours is unbent, be sure to bend it before installation.

When performing the next step, installation of the three pushbutton switches, be sure to install the two latching switches in the center and left-hand locations, when viewed from the component side of the board. Finally, solder the battery clip leads in place, observing red/black positive-negative polarity as indicated on the circuit board component layout diagram.

Once the main PCB is complete, as shown in Figure 8, it is time to wire the LCD board. The board will get a total of ten wires soldered to it, in two groups. There are two wire pigtails with plugs in the kit remnants, one with six wires, and one with four wires. The six-wire one has, in order from one end of the plug to the other, a brown, a red, an orange, a yellow, a green, and a blue wire. These wires will be inserted and soldered, respectively, into holes 1 through 6 on the LCD board. Similarly, the four-wire piece has, again in order from one end to the other, a brown, a red, an orange, and a yellow wire. These wires will go into holes 11 through 14, in sequence starting with the brown wire. The graphic at Figure 9 will show which wire color goes into which PCB hole. Solder these wires in place as well. These wires all go in from the side of the PCB with the hole numbers, and are soldered on the side with the LCD screen. It should be noted that the documentation parts list calls for right-angle plugs on these wire pigtails, but the ones in my kit were zero-degree types. The completed LCD board is shown in Figure 10.

After soldering the wires to the LCD board, the next step is to check the operating voltages on the boards. Plug both of the wire plugs from the LCD board onto the right-angle headers on the main board, with the brown wires to the left in each case when looking at the component side of the board. Snap a fresh nine-volt battery onto the battery snap and turn the unit on by pressing the left-hand latching pushbutton switch. Next, using a voltmeter, measure the voltage at pin 14 of the IC socket and at pin 2 of the LCD panel. Both locations should measure a nominal five volts. If the voltage is OK, you can move on with the assembly. If the voltage is not correct, check the installation and soldering of the LM7805 voltage regulator as well as the battery snaps. Start by verifying nine volts at pin 1 of the LM7805. If the nine volts are present but the five volts are not, check the installation and soldering of the 10µF electrolytic and the 0.1µF ceramic capacitors at pin 3 of the LM7805 voltage regulator. If no soldering errors such as solder bridges are found, the voltage regulator IC may be faulty.

If the five-volt supply is correct, shut the unit down and carefully install the PIC16F628 µC into the IC socket, observing the correct installation direction. Properly installed, the dotted or notched pin 1 end of the µC IC will be towards the test jack end of the main PCB. Be sure to get all eighteen pins into their slots in the IC socket without missing the socket to the outside and without allowing any pins to fold under the IC. It is sometimes helpful to gently press the IC at an angle on a tabletop to very gently and very slightly bend each row of pins towards the middle of the IC body.

Disconnect the battery from its snap. Then gently press a switch cap onto each of the pushbutton switches, aligning the shape of the switch shafts to the openings in the underside of the switch caps. Press them on until they snap into place.

Install the LCD panel into its opening in the upper half of the enclosure, aligning the four holes onto the studs and securing it there by gently tightening a 2-56 hex nut onto each stud. DO NOT over tighten the hex nuts. Remove the battery compartment cover from the lower half of the enclosure and pass the battery snap through the resulting opening. Align the main circuit board onto its four studs and secure it there with the 2-56 hex nuts provided. Again, DO NOT over tighten the hex nuts (Figure 11).

Snap the battery back onto its snap and then turn the meter on by depressing the left-hand pushbutton switch on the front panel. Using a small screwdriver, carefully adjust the 5kΩ trim pot until the display is visible without “shadow boxes” behind the characters. Turn the meter off.

Calibration

There are several facets to the calibration of the meter. The first is to check the free-running frequency of the oscillator and the calibration frequency of the oscillator. The calibration frequency should be within 71% ±10% of the free-running frequency. Calibration involves the use of the jumper pin cap and the four two-pin jumper headers on the main PCB. Figure 12 shows the locations of the four jumper headers.

We can check the free-running oscillator frequency (F1) first by taking the jumper cap and placing it on the two pins of J2, the second pair of jumper pins from the top of the PCB. Turn the unit on and the display will show the frequency in Hertz. With the 82µH inductor in circuit, the oscillator will run somewhere in the range of 58 kHz to 60 kHz. Mine runs right at 58.922 kHz - 0058922 on the meter display (Figure 13). To see the calibration frequency (F2) displayed, move the jumper cap to J1 - the first pair of pins from the top of the PCB. The display will now show the calibration frequency. Mine ran at 41.771 kHz (00041771 on the meter - Figure 14). This equates to 70.89% of the free-running frequency, and well within the ±10% frequency tolerance. It should be noted that if there is an indication of “0000000” on the display while checking oscillator frequencies, the oscillator is not running and some investigative work is called for. Also, if the difference between the free-running frequency and the calibration frequency is less than 2%, the relay is suspect. The two frequencies were measured using my bench-top frequency counter and found to be within 5 hertz of the displayed values.

The jumper cap is also used to calibrate the capacitance meter, if calibration is needed. To make that determination, start out by setting the meter in capacitance mode (center switch out) and then zeroing the capacitance function by momentarily pressing the right-hand switch. The meter will go through its calibration routine and will display “C = 0.0pF”. At this point, connect your standard capacitor - a device of a definite known value or a high-precision device - to the meter and read the display. If the meter reads within the tolerance of the capacitor, no calibration is required. For example, if your standard is a 0.001µF (1000pF) capacitor with a ±10% tolerance, the meter should read between 900 and 1100 picoFarads.

If the reading is outside the tolerance limits of your standard capacitor, calibration is accomplished by applying the jumper cap to either J3 or to J4. J3 is the third set of jumper pins from the top of the PCB, and J4 is the fourth set. Connecting the jumper cap to J3 will yield a decrease in indicated capacitance, while applying the jumper cap to J4 will produce on increase in displayed capacitance. The capacitance reading will continue to go up or down as long as the jumper is connected. When the reading gets to the value that you require for your capacitance standard, remove the jumper cap. The µC will remember the calibration value and use it in future measurements. Store the jumper cap by placing it on only one of the pins at J1 so that it is available if needed in the future.

Inductance calibration is automatically accomplished when the capacitance calibration is set.

Accessory Kit

The accessory kit assembly involves soldering alligator clips to the two test lead which are already terminated with banana pins, and the assembly of two miniature adapter circuit boards. One of the adapters - the LC adapter - gets only a four-pin SIP socket. The banana pins are already soldered in place as shipped. The second adapter is a varactor diode adapter, used for measuring the capacitance of a varactor diode. It has a pair of 100kΩ resistors and a 1µF monolithic ceramic capacitor in addition to the four-pin SIP socket. The assembled accessory kit is shown in Figure 15.

Final assembly requires that the LCD panel wires be plugged onto the main PCB right-angle headers, with the brown wires to the left on both plugs. Arrange the wires so that they will curl under the upper half of the enclosure cover, and install the end plate into the grooves in the enclosure end. Bring the two halves of the enclosure together, aligning the end plate into the slots in the second half and the three switches into their holes, and hold the two halves together while installing the four black securement screws provided for this purpose. Arrange the battery into the battery section and install the battery section cover to the lower half of the enclosure. If desired, print and affix a front panel label to the meter, and the job is complete (Figures 16 and 17).

Backlit LCD Panel

As I mentioned earlier in this article, I opted to replace the supplied non-backlit LCD panel with a backlit one. The original LCD panel is a Crystalfontz CFAH0802A-NYG-JT# 8X2 sunlight readable LCD unit. The backlit unit that I used is a Crystalfontz CFAH0802-YYH-JT# unit, which includes a 5VDC yellow-green LED backlight.

In order to make the backlight work, some modifications are necessary to the backlit LCD panel. These modifications consisted of closing one jumper location with a solder bridge, and soldering in a current limiting resistor at another location.

Refer to Figure 18 and note the locations identified as RA and J2 at the end of the LCD panel PCB opposite the end with the wire holes. One end of the RA location is connected through the PCB traces to Pin 2 of the PCB, which is the incoming 5VDC point. Similarly, one end of J2 is connected through the PCB traces to Pin 1 of the PCB, which is the 0VDC or ground pin. The opposite end of RA is tied to the A location, which is the anode of the backlight LED, and the second pin of J2 is tied to the K location, which is the backlight LED cathode.

Creating a solder bridge across J2 effectively grounds the cathode of the backlight LED. The requisite current-limiting resistor gets installed across the RA location, thus completing the power circuit for the backlight LED and providing for proper current limitation.

So now, the question becomes “What value resistor should be used at RA to provide for the proper current to the LED?” That answer comes from the Crystalfontz datasheet for the CFAH0802-YYH-JT# unit. According to the datasheet, the backlight LED current is typically 70mA, and the forward voltage is listed as 4.2VDC. OK - a 5.0VDC supply less 4.2V leaves 0.8 volts. Using Ohm’s Law and solving for resistance, R = E / I so R is equal to 0.8V / 0.07A - remember that we have to convert the 70mA to amperes. The resulting resistance would be 11.43Ω. By the way… the standard formula for finding an LED limiting resistor from voltage and current is to use the formula R = (VS – VF) / IF which is really just another way of saying the same thing… R = (5.0-4.2) / 0.07 = 0.8 / 0.07 which is equal to 11.429Ω. Ohm’s Law through the back door!

I installed an 18Ω 250mW resistor and called it a day. I also did not even bother to source a surface mount resistor for this, as I had the axial leaded 18Ω part in stock. It was an OK fit soldered to the PCB at the RA location. I could have gone with a 15Ω (or even a 10Ω) resistor just as easily either one would have worked OK. I chose the 18Ω because it would reduce their current towards to lower end of the current range (63mA to 84mA), would dim the LED very slightly and would possibly slightly extend the LED life. The 250mW was overkill, as the resistor would consume a mere 56mW, but it was what I had on hand. Figure 19 shows the modified LCD panel as installed into the meter enclosure.

Conclusion

This meter will find a home on my test bench. Of that, there is no doubt. However, I won’t really be happy with it until I have re-worked the software to give me English prompts. To that end, I already stock a few pieces of the PIC16F628A-I/P microcontroller, so I am ahead of the game, especially as Mouse and Digikey have no stock on these µC’s as of the date of this writing. I do not plan to overwrite the original; instead, I will work with another IC for my experimentation. I will find the time to do that in the not-too-distant future. Some time with MPLAB is called for.

Apart from the non-English prompts, my other complaints about this kit are the lack of a front panel label - an easy and inexpensive improvement that the kit maker should consider, especially as it would get his brand out there to be seen and remembered - and the complete lack of PCB legend screen prints. I mentioned this with the last HecKits build, and it is still a sore spot. I know that with my PCB manufacturer, there is no additional charge for the screen printing, so this is truly an egregious oversight in my opinion. It is one of the things that takes a first-class kit and relegates it to the lower levels, and certainly makes the build more onerous. My last gripe is that the parts actually shipped do not accurately match the parts list provided. Either provide the listed parts, or edit the parts list! I also think that a backlit LCD panel should be the standard equipment alternative rather than a builder-supplied upgrade.

So much for the cons… now for the pros. The meter is quick and responsive, and is more than adequately accurate. I like its compact size, and I appreciate the attention to detail expended in the mounting arrangements for the circuit boards. The fact that the maker provides the rudimentary nut driver says quite a bit. Someone thought about the limited clearance around some of the fastening hex nuts and provided a tool solution to make assembly simpler. The mounting studs or screws are locked in place, making installation of the boards a breeze. The battery compartment includes a rubber pad to keep the battery from rattling around, and the battery snap is of sturdy good quality. The kit maker’s decision to pre-solder the test jacks and banana pins was a good choice, as they are critical points that could be difficult for a less-experienced kit builder. The fit and finish of the meter is good.

All things considered, this one is probably a B+, but it would not take much to make it an A+. As HecKits grows, I would expect that some of these issues will be addressed. They need to be, because they really keep this from being a first-rate kit.